Page 434 - Complete Wireless Design

P. 434

Wireless Issues

Wireless Issues 433

Metallization is the conductive layer of the interconnecting traces and pads

placed onto the substrate. It can be made of copper, gold, or silver deposited on

the substrate board material. The entire PCB itself can be called a metallized

substrate in these hybrid applications. The board material is usually a type of

ceramic, such as alumina, aluminum nitride, or beryllia. These ceramics are

extremely rigid and are quite temperature stable, besides having a very high-

strength characteristic, attributes that make ceramics perfect as a substrate

material for hybrid applications. Alumina (aluminum oxide) is by far the low-

est in cost and most popular. It is a high-frequency (up to 25 GHz), very hard

substrate material that does not require a carrier (heavy metal stiffening

plate), and has a very high dielectric constant of around 9.8 (for small circuit

layout sizes). This material is used in applications that require rigidity,

strength, and temperature stability, along with decent thermal conductivity.

The next substrate, aluminum nitride, is found only in specialized hybrid

applications that require better thermal conductivity, but at a substantially

increased cost, over alumina. Beryllia (beryllium oxide), which is even higher

in cost than aluminum nitride, is seen in applications where low dielectric con-

stants are needed (around 6), as well as improved thermal conductivity.

However, Beryllia dust particles are toxic, and must not be inhaled when this

dangerous substrate material is machined.

10.6 Direct-Conversion Receivers

10.6.1 Introduction

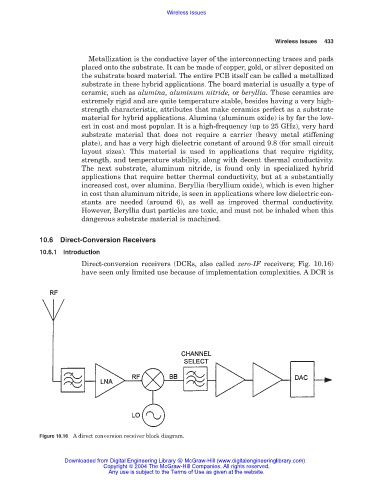

Direct-conversion receivers (DCRs, also called zero-IF receivers; Fig. 10.16)

have seen only limited use because of implementation complexities. A DCR is

Figure 10.16 A direct conversion receiver block diagram.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.