Page 119 - Compression Machinery for Oil and Gas

P. 119

106 SECTION II Types of Equipment

Several methods have been developed for dealing with fouling situations.

The surest method remains taking the compressor offline and cleaning out

the foulant to restore efficiency. This can be done during an overhaul by

mechanical means or done by performing an offline wash. However, this

requires shutting down the unit and losing production. Less costly methods that

focus on extending the time between cleanings have been developed such as

online washing and nonstick coatings.

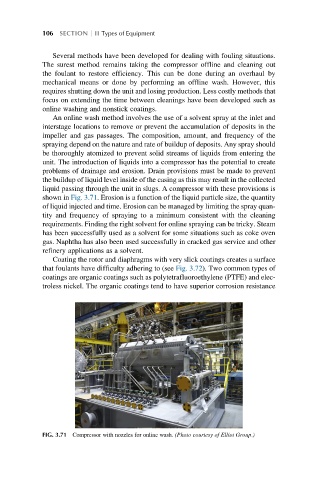

An online wash method involves the use of a solvent spray at the inlet and

interstage locations to remove or prevent the accumulation of deposits in the

impeller and gas passages. The composition, amount, and frequency of the

spraying depend on the nature and rate of buildup of deposits. Any spray should

be thoroughly atomized to prevent solid streams of liquids from entering the

unit. The introduction of liquids into a compressor has the potential to create

problems of drainage and erosion. Drain provisions must be made to prevent

the buildup of liquid level inside of the casing as this may result in the collected

liquid passing through the unit in slugs. A compressor with these provisions is

shown in Fig. 3.71. Erosion is a function of the liquid particle size, the quantity

of liquid injected and time. Erosion can be managed by limiting the spray quan-

tity and frequency of spraying to a minimum consistent with the cleaning

requirements. Finding the right solvent for online spraying can be tricky. Steam

has been successfully used as a solvent for some situations such as coke oven

gas. Naphtha has also been used successfully in cracked gas service and other

refinery applications as a solvent.

Coating the rotor and diaphragms with very slick coatings creates a surface

that foulants have difficulty adhering to (see Fig. 3.72). Two common types of

coatings are organic coatings such as polytetrafluoroethylene (PTFE) and elec-

troless nickel. The organic coatings tend to have superior corrosion resistance

FIG. 3.71 Compressor with nozzles for online wash. (Photo courtesy of Elliot Group.)