Page 116 - Compression Machinery for Oil and Gas

P. 116

Centrifugal Compressors Chapter 3 103

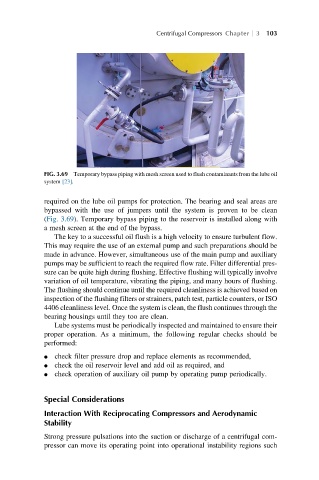

FIG. 3.69 Temporary bypass piping with mesh screen used to flush contaminants from the lube oil

system [23].

required on the lube oil pumps for protection. The bearing and seal areas are

bypassed with the use of jumpers until the system is proven to be clean

(Fig. 3.69). Temporary bypass piping to the reservoir is installed along with

a mesh screen at the end of the bypass.

The key to a successful oil flush is a high velocity to ensure turbulent flow.

This may require the use of an external pump and such preparations should be

made in advance. However, simultaneous use of the main pump and auxiliary

pumps may be sufficient to reach the required flow rate. Filter differential pres-

sure can be quite high during flushing. Effective flushing will typically involve

variation of oil temperature, vibrating the piping, and many hours of flushing.

The flushing should continue until the required cleanliness is achieved based on

inspection of the flushing filters or strainers, patch test, particle counters, or ISO

4406 cleanliness level. Once the system is clean, the flush continues through the

bearing housings until they too are clean.

Lube systems must be periodically inspected and maintained to ensure their

proper operation. As a minimum, the following regular checks should be

performed:

l check filter pressure drop and replace elements as recommended,

l check the oil reservoir level and add oil as required, and

l check operation of auxiliary oil pump by operating pump periodically.

Special Considerations

Interaction With Reciprocating Compressors and Aerodynamic

Stability

Strong pressure pulsations into the suction or discharge of a centrifugal com-

pressor can move its operating point into operational instability regions such