Page 111 - Compression Machinery for Oil and Gas

P. 111

Centrifugal Compressors Chapter 3 99

A B

D

C

E

H

G

F

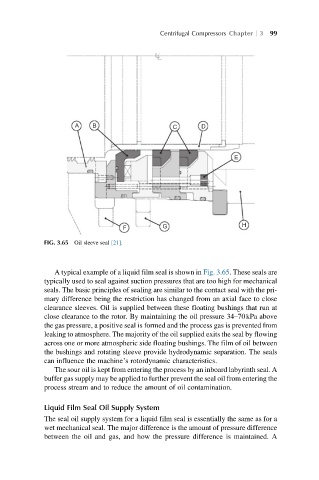

FIG. 3.65 Oil sleeve seal [21].

A typical example of a liquid film seal is shown in Fig. 3.65. These seals are

typically used to seal against suction pressures that are too high for mechanical

seals. The basic principles of sealing are similar to the contact seal with the pri-

mary difference being the restriction has changed from an axial face to close

clearance sleeves. Oil is supplied between these floating bushings that run at

close clearance to the rotor. By maintaining the oil pressure 34–70kPa above

the gas pressure, a positive seal is formed and the process gas is prevented from

leaking to atmosphere. The majority of the oil supplied exits the seal by flowing

across one or more atmospheric side floating bushings. The film of oil between

the bushings and rotating sleeve provide hydrodynamic separation. The seals

can influence the machine’s rotordynamic characteristics.

The sour oil is kept from entering the process by an inboard labyrinth seal. A

buffer gas supply may be applied to further prevent the seal oil from entering the

process stream and to reduce the amount of oil contamination.

Liquid Film Seal Oil Supply System

The seal oil supply system for a liquid film seal is essentially the same as for a

wet mechanical seal. The major difference is the amount of pressure difference

between the oil and gas, and how the pressure difference is maintained. A