Page 109 - Compression Machinery for Oil and Gas

P. 109

Centrifugal Compressors Chapter 3 97

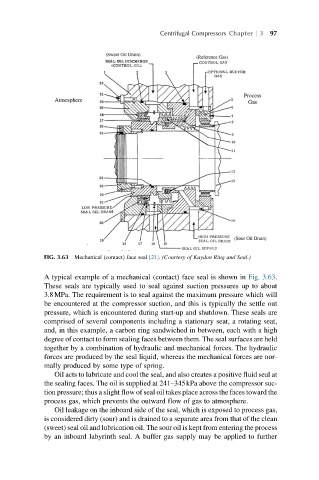

FIG. 3.63 Mechanical (contact) face seal [21]. (Courtesy of Kaydon Ring and Seal.)

A typical example of a mechanical (contact) face seal is shown in Fig. 3.63.

These seals are typically used to seal against suction pressures up to about

3.8MPa. The requirement is to seal against the maximum pressure which will

be encountered at the compressor suction, and this is typically the settle out

pressure, which is encountered during start-up and shutdown. These seals are

comprised of several components including a stationary seat, a rotating seat,

and, in this example, a carbon ring sandwiched in between, each with a high

degree of contact to form sealing faces between them. The seal surfaces are held

together by a combination of hydraulic and mechanical forces. The hydraulic

forces are produced by the seal liquid, whereas the mechanical forces are nor-

mally produced by some type of spring.

Oil acts to lubricate and cool the seal, and also creates a positive fluid seal at

the sealing faces. The oil is supplied at 241–345kPa above the compressor suc-

tion pressure; thus a slight flow of seal oil takes place across the faces toward the

process gas, which prevents the outward flow of gas to atmosphere.

Oil leakage on the inboard side of the seal, which is exposed to process gas,

is considered dirty (sour) and is drained to a separate area from that of the clean

(sweet) seal oil and lubrication oil. The sour oil is kept from entering the process

by an inboard labyrinth seal. A buffer gas supply may be applied to further