Page 104 - Compression Machinery for Oil and Gas

P. 104

Centrifugal Compressors Chapter 3 93

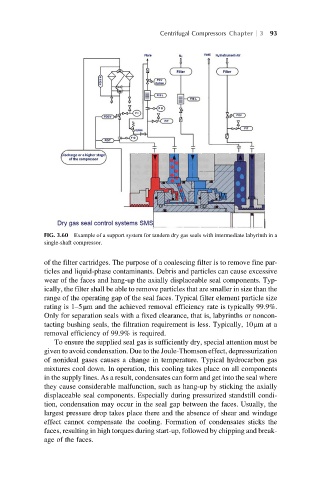

FIG. 3.60 Example of a support system for tandem dry gas seals with intermediate labyrinth in a

single-shaft compressor.

of the filter cartridges. The purpose of a coalescing filter is to remove fine par-

ticles and liquid-phase contaminants. Debris and particles can cause excessive

wear of the faces and hang-up the axially displaceable seal components. Typ-

ically, the filter shall be able to remove particles that are smaller in size than the

range of the operating gap of the seal faces. Typical filter element particle size

rating is 1–5μm and the achieved removal efficiency rate is typically 99.9%.

Only for separation seals with a fixed clearance, that is, labyrinths or noncon-

tacting bushing seals, the filtration requirement is less. Typically, 10μmat a

removal efficiency of 99.9% is required.

To ensure the supplied seal gas is sufficiently dry, special attention must be

given to avoid condensation. Due to the Joule-Thomson effect, depressurization

of nonideal gases causes a change in temperature. Typical hydrocarbon gas

mixtures cool down. In operation, this cooling takes place on all components

in the supply lines. As a result, condensates can form and get into the seal where

they cause considerable malfunction, such as hang-up by sticking the axially

displaceable seal components. Especially during pressurized standstill condi-

tion, condensation may occur in the seal gap between the faces. Usually, the

largest pressure drop takes place there and the absence of shear and windage

effect cannot compensate the cooling. Formation of condensates sticks the

faces, resulting in high torques during start-up, followed by chipping and break-

age of the faces.