Page 101 - Compression Machinery for Oil and Gas

P. 101

90 SECTION II Types of Equipment

The API 617 and 686 standards are quite detailed and specific in regards to

support structures and alignment provisions and should be followed. Base

plates, or individual sole plates for compressor and driver, should be aligned

before grouting on a concrete subbase or anchoring to structural steel supporting

members in order to provide a proper basis for alignment and leveling of com-

pressor and driver shafts. Mounting surfaces must be flat, have good surface

finish, and be parallel to each other. Jack screws are provided to allow shifting

the compressor horizontally and axially. Vertical jack screws are provided to

raise the compressor for shimming.

Auxiliary Systems/Supporting System

Seal Systems

The primary purpose of a seal system is safety. Emissions reduction, while an

objective, is of secondary importance.

Dry Gas

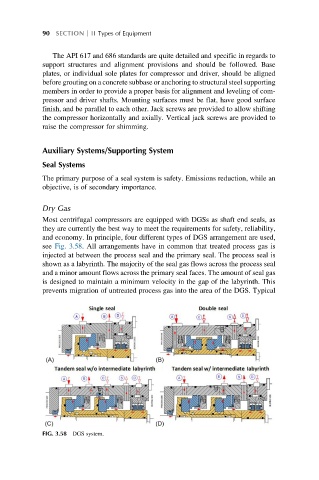

Most centrifugal compressors are equipped with DGSs as shaft end seals, as

they are currently the best way to meet the requirements for safety, reliability,

and economy. In principle, four different types of DGS arrangement are used,

see Fig. 3.58. All arrangements have in common that treated process gas is

injected at between the process seal and the primary seal. The process seal is

shown as a labyrinth. The majority of the seal gas flows across the process seal

and a minor amount flows across the primary seal faces. The amount of seal gas

is designed to maintain a minimum velocity in the gap of the labyrinth. This

prevents migration of untreated process gas into the area of the DGS. Typical

FIG. 3.58 DGS system.