Page 96 - Compression Machinery for Oil and Gas

P. 96

Centrifugal Compressors Chapter 3 85

0.8

Front cavity—Correlation

Front cavity—CFD analysis

Front cavity—Pressure measurement

Rear cavity—Correlation

0.7

Rear cavity—CFD analysis

0.6

Cavity swirl coefficient (q) 0.5

0.4

0.3

1 2 2 2

p(r)= p tip – — r(qw) (r tip – r )

2

0.2

0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09

Inlet flow coefficient (F)

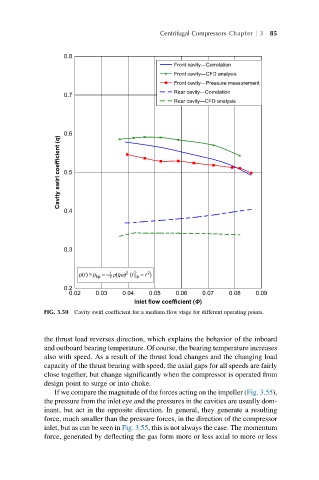

FIG. 3.50 Cavity swirl coefficient for a medium flow stage for different operating points.

the thrust load reverses direction, which explains the behavior of the inboard

and outboard bearing temperature. Of course, the bearing temperature increases

also with speed. As a result of the thrust load changes and the changing load

capacity of the thrust bearing with speed, the axial gaps for all speeds are fairly

close together, but change significantly when the compressor is operated from

design point to surge or into choke.

If we compare the magnitude of the forces acting on the impeller (Fig. 3.55),

the pressure from the inlet eye and the pressures in the cavities are usually dom-

inant, but act in the opposite direction. In general, they generate a resulting

force, much smaller than the pressure forces, in the direction of the compressor

inlet, but as can be seen in Fig. 3.55, this is not always the case. The momentum

force, generated by deflecting the gas form more or less axial to more or less