Page 91 - Compression Machinery for Oil and Gas

P. 91

80 SECTION II Types of Equipment

TABLE 3.2 Horizontal (X) and Vertical (Y) Shift in Foot Mounted Compressor

Centerline at a Discharge Temperature of 436K

Compressor Growth Compressor 436K

mm 0

X Inlet

mm 0.12

Y Inlet

mm 0

X Discharge

mm 1.05

Y Discharge

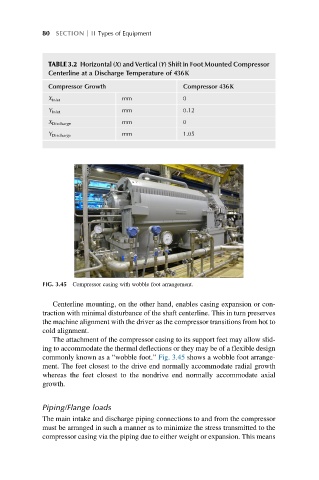

FIG. 3.45 Compressor casing with wobble foot arrangement.

Centerline mounting, on the other hand, enables casing expansion or con-

traction with minimal disturbance of the shaft centerline. This in turn preserves

the machine alignment with the driver as the compressor transitions from hot to

cold alignment.

The attachment of the compressor casing to its support feet may allow slid-

ing to accommodate the thermal deflections or they may be of a flexible design

commonly known as a “wobble foot.” Fig. 3.45 shows a wobble foot arrange-

ment. The feet closest to the drive end normally accommodate radial growth

whereas the feet closest to the nondrive end normally accommodate axial

growth.

Piping/Flange loads

The main intake and discharge piping connections to and from the compressor

must be arranged in such a manner as to minimize the stress transmitted to the

compressor casing via the piping due to either weight or expansion. This means