Page 112 - Compression Machinery for Oil and Gas

P. 112

100 SECTION II Types of Equipment

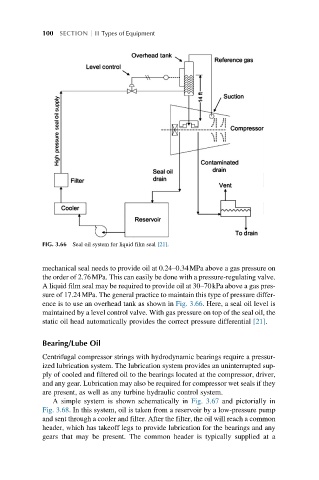

FIG. 3.66 Seal oil system for liquid film seal [21].

mechanical seal needs to provide oil at 0.24–0.34MPa above a gas pressure on

the order of 2.76MPa. This can easily be done with a pressure-regulating valve.

A liquid film seal may be required to provide oil at 30–70kPa above a gas pres-

sure of 17.24MPa. The general practice to maintain this type of pressure differ-

ence is to use an overhead tank as shown in Fig. 3.66. Here, a seal oil level is

maintained by a level control valve. With gas pressure on top of the seal oil, the

static oil head automatically provides the correct pressure differential [21].

Bearing/Lube Oil

Centrifugal compressor strings with hydrodynamic bearings require a pressur-

ized lubrication system. The lubrication system provides an uninterrupted sup-

ply of cooled and filtered oil to the bearings located at the compressor, driver,

and any gear. Lubrication may also be required for compressor wet seals if they

are present, as well as any turbine hydraulic control system.

A simple system is shown schematically in Fig. 3.67 and pictorially in

Fig. 3.68. In this system, oil is taken from a reservoir by a low-pressure pump

and sent through a cooler and filter. After the filter, the oil will reach a common

header, which has takeoff legs to provide lubrication for the bearings and any

gears that may be present. The common header is typically supplied at a