Page 110 - Compression Machinery for Oil and Gas

P. 110

98 SECTION II Types of Equipment

prevent the seal oil from entering the process stream and to reduce the amount of

oil contamination. Little to no gas leakage occurs across the actual seal. Most

emissions are actually from seal oil degassing due to the oil absorbing gas on the

inboard side.

The sweet uncontaminated oil is drained back directly to the reservoir. The

contaminated oil is sent to a separate drain cavity and is either discarded or

degassed. If the contaminated oil is reconditioned, it must first be sent to a

degassing tank to release the entrained gas by heating the oil. This eliminates

the possibility of contaminating the fresh lube and seal oil reservoirs. Then, the

degassed oil is sent directly to the reservoir to be reused. The released gas may

be vented, flared, returned to the compressor inlet, or used as fuel in some cases.

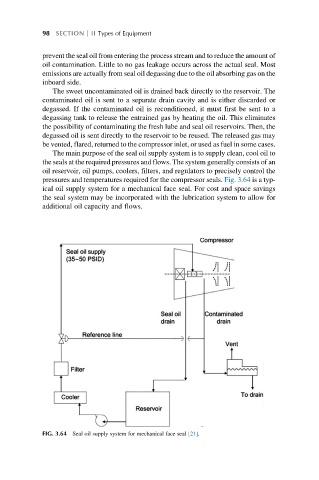

The main purpose of the seal oil supply system is to supply clean, cool oil to

the seals at the required pressures and flows. The system generally consists of an

oil reservoir, oil pumps, coolers, filters, and regulators to precisely control the

pressures and temperatures required for the compressor seals. Fig. 3.64 is a typ-

ical oil supply system for a mechanical face seal. For cost and space savings

the seal system may be incorporated with the lubrication system to allow for

additional oil capacity and flows.

FIG. 3.64 Seal oil supply system for mechanical face seal [21].