Page 383 - Compression Machinery for Oil and Gas

P. 383

364 SECTION II Types of Equipment

FIG. 7.52 Thermocouples to indicate casing temperature.

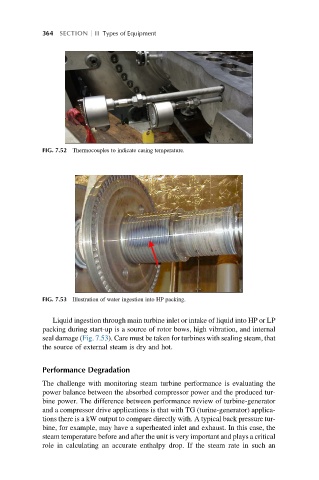

FIG. 7.53 Illustration of water ingestion into HP packing.

Liquid ingestion through main turbine inlet or intake of liquid into HP or LP

packing during start-up is a source of rotor bows, high vibration, and internal

seal damage (Fig. 7.53). Care must be taken for turbines with sealing steam, that

the source of external steam is dry and hot.

Performance Degradation

The challenge with monitoring steam turbine performance is evaluating the

power balance between the absorbed compressor power and the produced tur-

bine power. The difference between performance review of turbine-generator

and a compressor drive applications is that with TG (turine-generator) applica-

tions there is a kW output to compare directly with. A typical back pressure tur-

bine, for example, may have a superheated inlet and exhaust. In this case, the

steam temperature before and after the unit is very important and plays a critical

role in calculating an accurate enthalpy drop. If the steam rate in such an