Page 40 - Compression Machinery for Oil and Gas

P. 40

32 SECTION II Types of Equipment

higher ratios. In gas gathering, we may find pressure ratios of 25. The limits for

centrifugal compressors are typically either due to rotordynamic concerns,

which limit the speed and length of the rotor, or by temperature limits. Higher

pressure ratios may require multiple compressor bodies per train, and the

capability for intercooling. The operating range required also depends on the

application. Since for many applications, pressure ratio and flow are correlated

by the compression system, range has to be seen in that context. On the other

hand, many applications only see one distinct operating condition. Depending

on the range of operating conditions, different control methods (variable speed,

variable geometry, recycle) may be used. For applications that require the

compressor to cover a wide range of operating conditions, good compressor

efficiency over a wide range is usually more important than high peak

efficiency.

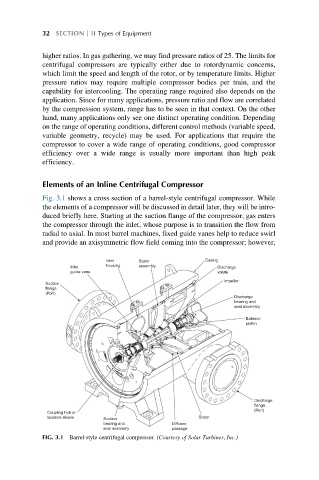

Elements of an Inline Centrifugal Compressor

Fig. 3.1 shows a cross section of a barrel-style centrifugal compressor. While

the elements of a compressor will be discussed in detail later, they will be intro-

duced briefly here. Starting at the suction flange of the compressor, gas enters

the compressor through the inlet, whose purpose is to transition the flow from

radial to axial. In most barrel machines, fixed guide vanes help to reduce swirl

and provide an axisymmetric flow field coming into the compressor; however,

Casing

Inlet Stator

housing

assembly

Inlet

Discharge

guide vane volute

Impeller

Suction

flange

(Port)

Discharge

bearing and

seal assembly

Balance

piston

Discharge

flange

(Port)

Coupling hub or

balance sleeve Stator

Suction

bearing and Diffuser

seal assembly passage

FIG. 3.1 Barrel-style centrifugal compressor. (Courtesy of Solar Turbines, Inc.)