Page 475 - Compression Machinery for Oil and Gas

P. 475

Compressor Testing Chapter 12 455

TABLE 12.1 In-Practice Achievable Uncertainty for Measured Performance

Test Parameters

Recommended

Measurement Uncertainty

Pressure 0.3%–1.0% full

scale

Temperature 0.5–7.0°F

Flow 0.5%–2.0% of value

Gas composition (density, compressibility, gas constant, 0.2%–3.0% of value

specific heat, energy content)

Piston position (encoder) 0.1%–0.3% of 360

degree

Axial and Centrifugal Compressors

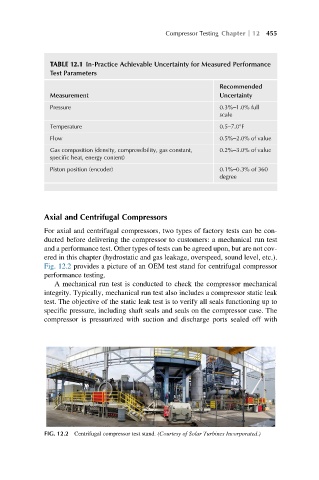

For axial and centrifugal compressors, two types of factory tests can be con-

ducted before delivering the compressor to customers: a mechanical run test

and a performance test. Other types of tests can be agreed upon, but are not cov-

ered in this chapter (hydrostatic and gas leakage, overspeed, sound level, etc.).

Fig. 12.2 provides a picture of an OEM test stand for centrifugal compressor

performance testing.

A mechanical run test is conducted to check the compressor mechanical

integrity. Typically, mechanical run test also includes a compressor static leak

test. The objective of the static leak test is to verify all seals functioning up to

specific pressure, including shaft seals and seals on the compressor case. The

compressor is pressurized with suction and discharge ports sealed off with

FIG. 12.2 Centrifugal compressor test stand. (Courtesy of Solar Turbines Incorporated.)