Page 129 -

P. 129

Production and Supply Chain Management Information Systems

adversarial relationship between suppliers and their customers. In recent years, more

companies have begun to realize that they are part of a supply chain, and if the supply

chain is more efficient, all participants in the chain can benefit. Collaboration can

frequently achieve more than competition, and ERP systems can play a key role in

collaborative planning.

109

Working with suppliers in a collaborative fashion requires trust among all parties. A

company opens its records to its suppliers, and suppliers can read certain company data

because of common data formats. Working with suppliers in this way cuts down on

paperwork and response times. Reductions in paperwork, savings in time, and other

efficiency improvements translate into cost savings for the company and the suppliers.

ERP lets companies and suppliers share information (sales, inventory, production plans,

and so on) in real time throughout the supply chain. This allows all parties to eliminate

from the supply chain costs that do not add value to the product (such as inventory,

overtime, changeovers, and spoilage), while simultaneously improving customer service.

The Traditional Supply Chain

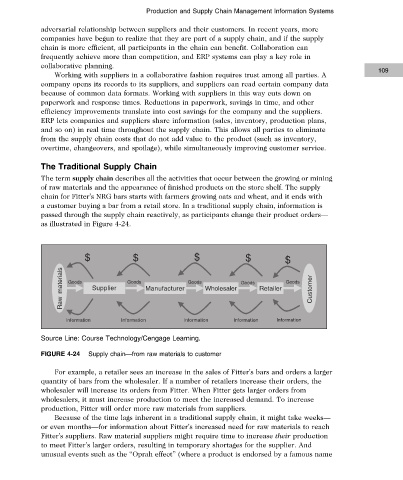

The term supply chain describes all the activities that occur between the growing or mining

of raw materials and the appearance of finished products on the store shelf. The supply

chain for Fitter’s NRG bars starts with farmers growing oats and wheat, and it ends with

a customer buying a bar from a retail store. In a traditional supply chain, information is

passed through the supply chain reactively, as participants change their product orders—

as illustrated in Figure 4-24.

Source Line: Course Technology/Cengage Learning.

FIGURE 4-24 Supply chain—from raw materials to customer

For example, a retailer sees an increase in the sales of Fitter’s bars and orders a larger

quantity of bars from the wholesaler. If a number of retailers increase their orders, the

wholesaler will increase its orders from Fitter. When Fitter gets larger orders from

wholesalers, it must increase production to meet the increased demand. To increase

production, Fitter will order more raw materials from suppliers.

Because of the time lags inherent in a traditional supply chain, it might take weeks—

or even months—for information about Fitter’s increased need for raw materials to reach

Fitter’s suppliers. Raw material suppliers might require time to increase their production

to meet Fitter’s larger orders, resulting in temporary shortages for the supplier. And

unusual events such as the “Oprah effect” (where a product is endorsed by a famous name

Copyright 2012 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.