Page 438 - Construction Waterproofing Handbook

P. 438

10.40 CHAPTER TEN

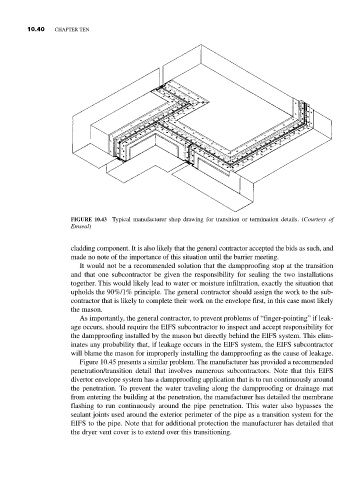

FIGURE 10.43 Typical manufacturer shop drawing for transition or termination details. (Courtesy of

Emseal)

cladding component. It is also likely that the general contractor accepted the bids as such, and

made no note of the importance of this situation until the barrier meeting.

It would not be a recommended solution that the dampproofing stop at the transition

and that one subcontractor be given the responsibility for sealing the two installations

together. This would likely lead to water or moisture infiltration, exactly the situation that

upholds the 90%/1% principle. The general contractor should assign the work to the sub-

contractor that is likely to complete their work on the envelope first, in this case most likely

the mason.

As importantly, the general contractor, to prevent problems of “finger-pointing” if leak-

age occurs, should require the EIFS subcontractor to inspect and accept responsibility for

the dampproofing installed by the mason but directly behind the EIFS system. This elim-

inates any probability that, if leakage occurs in the EIFS system, the EIFS subcontractor

will blame the mason for improperly installing the dampproofing as the cause of leakage.

Figure 10.45 presents a similar problem. The manufacturer has provided a recommended

penetration/transition detail that involves numerous subcontractors. Note that this EIFS

divertor envelope system has a dampproofing application that is to run continuously around

the penetration. To prevent the water traveling along the dampproofing or drainage mat

from entering the building at the penetration, the manufacturer has detailed the membrane

flashing to run continuously around the pipe penetration. This water also bypasses the

sealant joints used around the exterior perimeter of the pipe as a transition system for the

EIFS to the pipe. Note that for additional protection the manufacturer has detailed that

the dryer vent cover is to extend over this transitioning.