Page 268 - Corrosion Engineering Principles and Practice

P. 268

242 C h a p t e r 7 C o r r o s i o n F a i l u r e s , F a c t o r s , a n d C e l l s 243

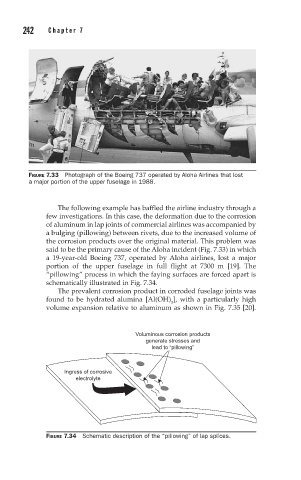

FIGURE 7.33 Photograph of the Boeing 737 operated by Aloha Airlines that lost

a major portion of the upper fuselage in 1988.

The following example has baffled the airline industry through a

few investigations. In this case, the deformation due to the corrosion

of aluminum in lap joints of commercial airlines was accompanied by

a bulging (pillowing) between rivets, due to the increased volume of

the corrosion products over the original material. This problem was

said to be the primary cause of the Aloha incident (Fig. 7.33) in which

a 19-year-old Boeing 737, operated by Aloha airlines, lost a major

portion of the upper fuselage in full flight at 7300 m [19]. The

“pillowing” process in which the faying surfaces are forced apart is

schematically illustrated in Fig. 7.34.

The prevalent corrosion product in corroded fuselage joints was

found to be hydrated alumina [Al(OH) ], with a particularly high

3

volume expansion relative to aluminum as shown in Fig. 7.35 [20].

Voluminous corrosion products

generate stresses and

lead to “pillowing”

Ingress of corrosive

electrolyte

FIGURE 7.34 Schematic description of the “pillowing” of lap splices.