Page 326 - Corrosion Engineering Principles and Practice

P. 326

296 C h a p t e r 8 C o r r o s i o n b y W a t e r 297

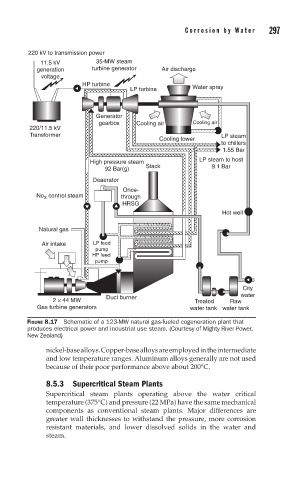

220 kV to transmission power

11.5 kV 35-MW steam

generation turbine generator Air discharge

voltage

HP turbine

LP turbine Water spray

Generator

gearbox Cooling air Cooling air

220/11.5 kV

Transformer LP steam

Cooling tower

to chillers

1.55 Bar

High pressure steam LP steam to host

92 Bar(g) Stack 9.1 Bar

Deaerator

Once-

No control steam through

X

HRSG

Hot well

Natural gas

Air intake LP feed

pump

HP feed

pump

City

2 × 44 MW Duct burner Treated Raw water

Gas turbine generators water tank water tank

FIGURE 8.17 Schematic of a 123-MW natural gas-fueled cogeneration plant that

produces electrical power and industrial use steam. (Courtesy of Mighty River Power,

New Zealand)

nickel-base alloys. Copper-base alloys are employed in the intermediate

and low temperature ranges. Aluminum alloys generally are not used

because of their poor performance above about 200°C.

8.5.3 Supercritical Steam Plants

Supercritical steam plants operating above the water critical

temperature (375°C) and pressure (22 MPa) have the same mechanical

components as conventional steam plants. Major differences are

greater wall thicknesses to withstand the pressure, more corrosion

resistant materials, and lower dissolved solids in the water and

steam.