Page 329 - Corrosion Engineering Principles and Practice

P. 329

300 C h a p t e r 8 C o r r o s i o n b y W a t e r 301

Boiling water reactor designs can be modified to accommodate a

superheater to raise the steam temperature for improved efficiency.

Experimental nuclear superheaters have been built to superheat the

steam from the boiling water reactor. Corrosion rates for stainless steels

and nickel alloys under heat transfer in the 600°C temperature range are

about 25 µm/y. However, experience has shown that even minute

amounts of entrained moisture in the entering steam can carry sufficient

chlorides that cracking of the stainless steel cladding of the nuclear fuel

elements may ultimately ensue. Alloys with higher nickel contents (e.g.,

N08800, N06600, or N06690) have resisted SCC under these conditions.

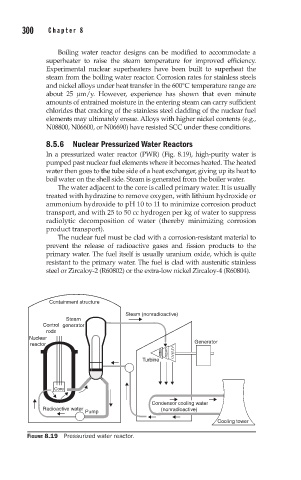

8.5.6 Nuclear Pressurized Water Reactors

In a pressurized water reactor (PWR) (Fig. 8.19), high-purity water is

pumped past nuclear fuel elements where it becomes heated. The heated

water then goes to the tube side of a heat exchanger, giving up its heat to

boil water on the shell side. Steam is generated from the boiler water.

The water adjacent to the core is called primary water. It is usually

treated with hydrazine to remove oxygen, with lithium hydroxide or

ammonium hydroxide to pH 10 to 11 to minimize corrosion product

transport, and with 25 to 50 cc hydrogen per kg of water to suppress

radiolytic decomposition of water (thereby minimizing corrosion

product transport).

The nuclear fuel must be clad with a corrosion-resistant material to

prevent the release of radioactive gases and fission products to the

primary water. The fuel itself is usually uranium oxide, which is quite

resistant to the primary water. The fuel is clad with austenitic stainless

steel or Zircaloy-2 (R60802) or the extra-low nickel Zircaloy-4 (R60804).

Containment structure

Steam (nonradioactive)

Steam

Control generator

rods

Nuclear

reactor Generator

Turbine

Core

Condensor cooling water

Radioactive water (nonradioactive)

Pump

Cooling tower

FIGURE 8.19 Pressurized water reactor.