Page 328 - Corrosion Engineering Principles and Practice

P. 328

298 C h a p t e r 8 C o r r o s i o n b y W a t e r 299

the manufacture of marketable products, simply do not give adequate

technical attention to the details of boiler feedwater chemistry. Many

chemical converters, catalytic converters, or other waste heat boilers have

failed from steam-generating side corrosion due to such inattention.

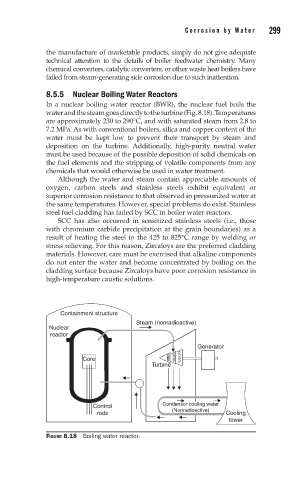

8.5.5 Nuclear Boiling Water Reactors

In a nuclear boiling water reactor (BWR), the nuclear fuel boils the

water and the steam goes directly to the turbine (Fig. 8.18). Temperatures

are approximately 230 to 290°C, and with saturated steam from 2.8 to

7.2 MPa. As with conventional boilers, silica and copper content of the

water must be kept low to prevent their transport by steam and

deposition on the turbine. Additionally, high-purity neutral water

must be used because of the possible deposition of solid chemicals on

the fuel elements and the stripping of volatile components from any

chemicals that would otherwise be used in water treatment.

Although the water and steam contain appreciable amounts of

oxygen, carbon steels and stainless steels exhibit equivalent or

superior corrosion resistance to that observed in pressurized water at

the same temperatures. However, special problems do exist. Stainless

steel fuel cladding has failed by SCC in boiler water reactors.

SCC has also occurred in sensitized stainless steels (i.e., those

with chromium carbide precipitation at the grain boundaries) as a

result of heating the steel in the 425 to 825°C range by welding or

stress relieving. For this reason, Zircaloys are the preferred cladding

materials. However, care must be exercised that alkaline components

do not enter the water and become concentrated by boiling on the

cladding surface because Zircaloys have poor corrosion resistance in

high-temperature caustic solutions.

Containment structure

Steam (nonradioactive)

Nuclear

reactor

Generator

Core

Turbine

Control Condensor cooling water

rods (Nonradioactive) Cooling

tower

FIGURE 8.18 Boiling water reactor.