Page 390 - Corrosion Engineering Principles and Practice

P. 390

358 C h a p t e r 9 A t m o s p h e r i c C o r r o s i o n 359

Distance AA

to sea ≤ 4.5 km

> 4.5 km

≤ 7.1 g m –3 Humidity ≤ 7.1 g m –3

or

≤ 125 cm/yr rain > 125 cm/yr

–3

> 43 mg m –3 > 43 mg m

–3

> 61 mg m

–3

> 61 mg m > 36 mg m –3

> 36 mg m –3

SO SO

2

2

B TSP TSP A

O 3 O 3

≤ 43 mg m –3 ≤ 43 mg m –3

≤ 61 mg m –3 ≤ 61 mg m –3

≤ 36 mg m –3 ≤ 36 mg m –3

C B

Expected corrosion damage

AA Very Severe B Moderate

A Severe C Mild

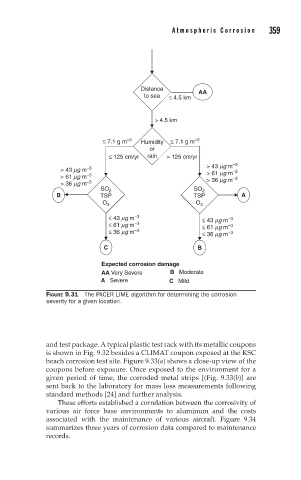

FIGURE 9.31 The PACER LIME algorithm for determining the corrosion

severity for a given location.

and test package. A typical plastic test rack with its metallic coupons

is shown in Fig. 9.32 besides a CLIMAT coupon exposed at the KSC

beach corrosion test site. Figure 9.33(a) shows a close-up view of the

coupons before exposure. Once exposed to the environment for a

given period of time, the corroded metal strips [(Fig. 9.33(b)] are

sent back to the laboratory for mass loss measurements following

standard methods [24] and further analysis.

These efforts established a correlation between the corrosivity of

various air force base environments to aluminum and the costs

associated with the maintenance of various aircraft. Figure 9.34

summarizes three years of corrosion data compared to maintenance

records.