Page 493 - Corrosion Engineering Principles and Practice

P. 493

460 C h a p t e r 1 1 M a t e r i a l s S e l e c t i o n , Te s t i n g , a n d D e s i g n C o n s i d e r a t i o n s 461

(a) (b)

New grout Old grout

(d)

(c)

(e)

(f)

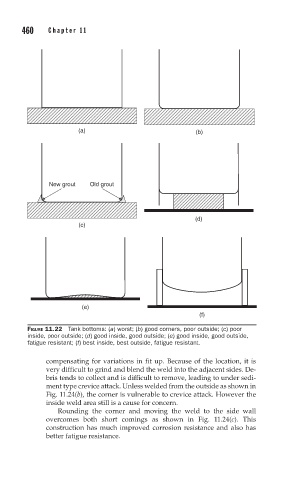

FIGURE 11.22 Tank bottoms: (a) worst; (b) good corners, poor outside; (c) poor

inside, poor outside; (d) good inside, good outside; (e) good inside, good outside,

fatigue resistant; (f) best inside, best outside, fatigue resistant.

compensating for variations in fit up. Because of the location, it is

very difficult to grind and blend the weld into the adjacent sides. De-

bris tends to collect and is difficult to remove, leading to under sedi-

ment type crevice attack. Unless welded from the outside as shown in

Fig. 11.24(b), the corner is vulnerable to crevice attack. However the

inside weld area still is a cause for concern.

Rounding the corner and moving the weld to the side wall

overcomes both short comings as shown in Fig. 11.24(c). This

construction has much improved corrosion resistance and also has

better fatigue resistance.