Page 549 - Corrosion Engineering Principles and Practice

P. 549

512 C h a p t e r 1 2 C o r r o s i o n a s a R i s k 513

spends approximately seven billion dollars per year on corrosion

control. This figure includes operations and maintenance activities,

capital expenditures, and corrosion failure repairs [18]. The tools most

commonly used by operators to verify pipeline integrity include both

external and internal direct assessments, hydrostatic testing, and in-

line inspection (ILI). Each of these tools can be used under various

circumstances for baseline assessments and future reassessments.

12.7.1 External Corrosion Damage Assessment

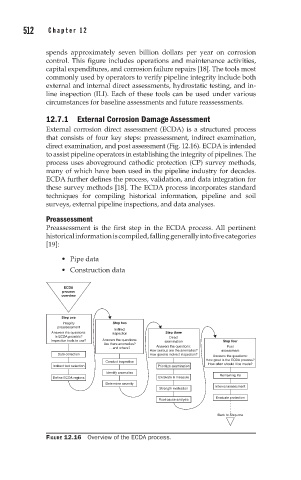

External corrosion direct assessment (ECDA) is a structured process

that consists of four key steps: preassessment, indirect examination,

direct examination, and post assessment (Fig. 12.16). ECDA is intended

to assist pipeline operators in establishing the integrity of pipelines. The

process uses aboveground cathodic protection (CP) survey methods,

many of which have been used in the pipeline industry for decades.

ECDA further defines the process, validation, and data integration for

these survey methods [18]. The ECDA process incorporates standard

techniques for compiling historical information, pipeline and soil

surveys, external pipeline inspections, and data analyses.

Preassessment

Preassessment is the first step in the ECDA process. All pertinent

historical information is compiled, falling generally into five categories

[19]:

• Pipe data

• Construction data

ECDA

process

overview

Step one

Integrity Step two

preassessment Indirect

Answers the questions: inspection Step three

Is ECDA possible? Direct

Inspection tools to use? Answers the questions: examination Step four

Are there anomalies?

... and where? Answers the questions: Post

How serious are the anomalies? assessment

Data collection How good is indirect inspection? Answers the questions:

How good is the ECDA process?

Conduct inspection

Indirect tool selection Prioritize examination How often should it be made?

Identify anomalies Remaining life

Define ECDA regions Excavate & measure

Determine severity

Strength evaluation Interval assessment

Evaluate protection

Root cause analysis

Back to Step one

FIGURE 12.16 Overview of the ECDA process.