Page 640 - Corrosion Engineering Principles and Practice

P. 640

C h a p t e r 1 4

600

C 3 : Medium—Urban and industrial atmospheres, moderate sulfur dioxide pollution; coastal areas with low salinity

Full Repaint occurs at Year of Maintenance Repaint + 50% of “P ” Life (Maintenance Repaint Year + [“P ” × 0.50].

C 5-I : Very High, Industry—Industrial areas with high humidity and aggressive atmosphere

Touch-Up painting occurs at Practical or “P ” service life as listed in this Table

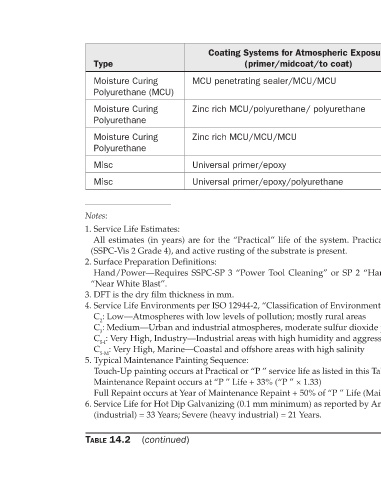

Coating Systems for Atmospheric Exposure Number Surface C 5-M C 5-I C 3 C 2 DFT of Coats Preparation (primer/midcoat/to coat) 9 7 14 15 1.8 3 Hand/power MCU penetrating sealer/MCU/MCU 15 15 21 30 2.3 3 Blast Zinc rich MCU/polyurethane/ polyurethane 15 14 21 29 2.3 3 Blast Zinc rich MCU/MCU

4. Service Life Environments per ISO 12944-2, “Classification of Environments”:

C 2 : Low—Atmospheres with low levels of pollution; mostly rural areas

C 5-M : Very High, Marine—Coastal and offshore areas with high salinity

Moisture Curing Polyurethane (MCU) Moisture Curing Polyurethane Moisture Curing Polyurethane 1. Service Life Estimates: 2. Surface Preparation Definitions: “Near White Blast”. 3. DFT is the dry film thickness in mm. 5. Typical Maintenance Painting Sequence: Maintenance Repaint occurs at “P ” Life

Type Misc Misc Notes: TABLE 14.2