Page 642 - Corrosion Engineering Principles and Practice

P. 642

602

SW

14

8

6

FW

17

8

9

PW

—

10

12

DFT

2.0

1.5

4.1

of Coats

2

2

2

Preparation

Blast

Blast

Blast

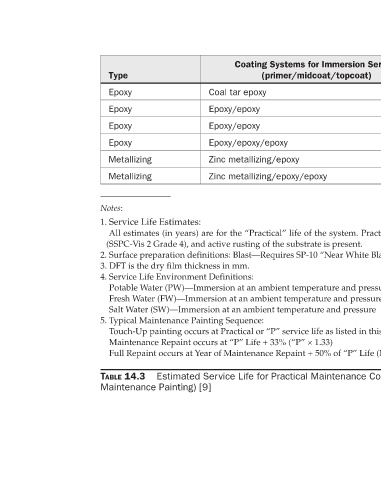

Coating Systems for Immersion Service Number Surface C h a p t e r 1 4 11 12 15 2.5 3 Blast Epoxy/epoxy/epoxy 15 17 20 2.3 2 Blast Zinc metallizing/epoxy 18 20 24 3.3 3 Blast Zinc metallizing/epoxy/epoxy All estimates (in years) are for the “Practical” life of the system. Practical l

(primer/midcoat/topcoat)

Coal tar epoxy

Epoxy/epoxy

Epoxy/epoxy

Type Epoxy Epoxy Epoxy Epoxy Metallizing Metallizing Notes: 1. Service Life Estimates: 3. DFT is the dry film thickness in mm. 4. Service Life Environment Definitions: 5. Typical Maintenance Painting Sequence: Maintenance Repaint occurs at “P” Life + 33% (“P” × 1.33) TABLE 14.3 Maintenance Paintin