Page 646 - Corrosion Engineering Principles and Practice

P. 646

604 C h a p t e r 1 4 P r o t e c t i v e C o a t i n g s 605

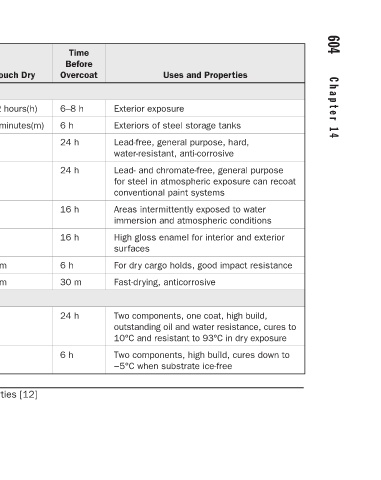

Uses and Properties Exteriors of steel storage tanks Lead-free, general purpose, hard, Lead- and chromate-free, general purpose for steel in atmospheric exposure can recoat Areas intermittently exposed to water immersion and atmospheric conditions High gloss enamel for interior and exterior For dry carg

Exterior exposure water-resistant, anti-corrosive conventional paint systems surfaces Fast-drying, anticorrosive −5°C when substrate ice-free

Time Before Overcoat 6–8 h 6 h 24 h 24 h 16 h 16 h 6 h 30 m 24 h 6 h

Touch Dry 1–2 hours(h) 45 minutes(m) 2 h 2 h 1 h 1 h 45 m 10 m 7 h 4 h

Thickness (µm) 38 25 38 38 38 38 25 25 400 125–500

% Solid 32 52 42 54 55 54 48 32 80 71 Modern Organic Coating Materials, Applications, and Properties [12]

Coating type Alkyds Fast-dry enamel Tank-finish aluminum Red oxide primer Zinc phosphate primer General purpose gloss High gloss, high quality finish coat Aluminum finishing coat All purpose primer Coal Tar Epoxies Polyamide cured coal tar Polyamine-adduct-cured coal tar TABLE 14.4