Page 650 - Corrosion Engineering Principles and Practice

P. 650

606 C h a p t e r 1 4 P r o t e c t i v e C o a t i n g s 607

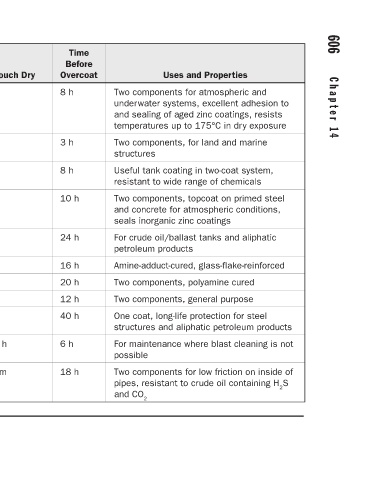

Uses and Properties Two components for atmospheric and underwater systems, excellent adhesion to and sealing of aged zinc coatings, resists temperatures up to 175°C in dry exposure Two components, for land and marine Useful tank coating in two-coat system, resistant to wide range of chemicals Two components

Time Before Overcoat 8 h 3 h structures 8 h 10 h 24 h 16 h 20 h 12 h 40 h 6 h possible 18 h and CO 2

Touch Dry

1 h 2 h 3 h 3 h 4 h 3 h 3 h 2 h 5 h 2.5 h 45 m

Thickness (µm) 38 75–150 250 75–150 300 250–500 75–150 150 > 300 125–200 50–100

% Solid 57 61 78 55 100 88 55 62 100 80 60

Epoxy-based adhesion primer/ sealer Micaceous iron oxide epoxy primer Epoxy high build/finish coat High build abrasion resistant epoxy High build, recoatable epoxy High build, surface-tolerant epoxy (continued)

Coating type High build epoxy lining Solvent-free epoxy Acid-resistant epoxy Solvent-free epoxy Phenolic epoxy TABLE 14.4