Page 652 - Corrosion Engineering Principles and Practice

P. 652

606 C h a p t e r 1 4 P r o t e c t i v e C o a t i n g s 607

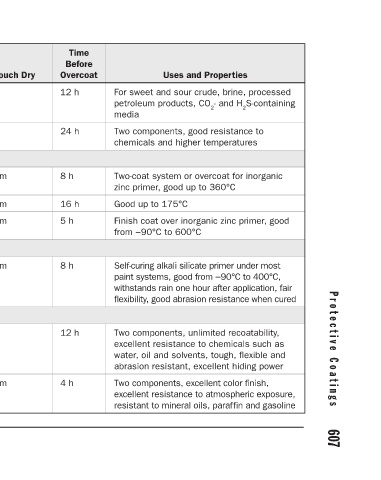

For sweet and sour crude, brine, processed Two components, good resistance to chemicals and higher temperatures Two-coat system or overcoat for inorganic zinc primer, good up to 360°C Good up to 175°C Finish coat over inorganic zinc primer, good from −90°C to 600°C Self-curing alkali silicate primer u

Uses and Properties petroleum products, CO 2 - and H 2 S-containing withstands rain one hour after application, fair flexibility, good abrasion resistance when cured excellent resistance to atmospheric exposure, resistant to mineral oils, paraffin and gasoline

Time Before Overcoat 12 h media 24 h 8 h 16 h 5 h 8 h 12 h 4 h

Touch Dry

2 h 30 m 60 m 60 m 15 m 1h 30 m

Thickness (µm) 75–150 100 35 25 50 100–125 51–76 50

% Solid 55 66 28 50 38 65 60 41

Coating type Phenolic epoxy lining Phenolic epoxy tank lining primer/ intermediate and finish formulations Heat Resistant Coatings Heat-resisting aluminum Heat-resisting aluminum finish Moisture-cured inorganic silicate Inorganic Zincs Water-based inorganic zinc primer Polyurethanes High solids aliphatic