Page 651 - Corrosion Engineering Principles and Practice

P. 651

C h a p t e r 1 4

606

excellent resistance to atmospheric exposure,

petroleum products, CO 2- and H 2 S-containing

flexibility, good abrasion resistance when cured

For sweet and sour crude, brine, processed

water, oil and solvents, tough, flexible and

excellent resistance to chemicals such as

abrasion resistant, excellent hiding power

Two components, unlimited recoatability,

Two components, excellent color finish,

Uses and Properties

media

Overcoat

Before

Time

12 h

12 h

4 h

Touch Dry

30 m

2 h Two components, good resistance to 24 h chemicals and higher temperatures Two-coat system or overcoat for inorganic 8 h 30 m zinc primer, good up to 360°C Good up to 175°C 16 h 60 m Finish coat over inorganic zinc primer, good 5 h 60 m from −90°C to 600°C Self-curing alkali silicate pr

1h

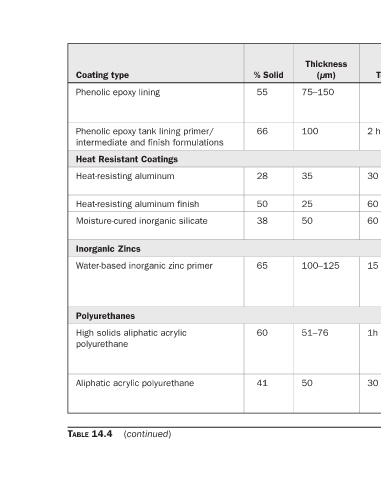

Thickness (µm) 75–150 100 35 25 50 100–125 51–76 50

% Solid 55 66 28 50 38 65 60 41

Coating type Phenolic epoxy lining Phenolic epoxy tank lining primer/ intermediate and finish formulations Heat Resistant Coatings Heat-resisting aluminum Heat-resisting aluminum finish Moisture-cured inorganic silicate Inorganic Zincs Water-based inorganic zinc primer Polyurethanes High solids aliphatic