Page 698 - Corrosion Engineering Principles and Practice

P. 698

652 C h a p t e r 1 4 P r o t e c t i v e C o a t i n g s 653

Environmental test rooms: Environmental test rooms which permit

various combinations of temperature, fogging, humidity levels,

and shower effects to simulate rain can reproduce in an accelerated

mode many of the factors present in an actual exposure. For the

most part, these tests use small cut or machined specimens, but

assemblies of simulated components and complete systems can

also be tested as shown in Fig. 11.35.

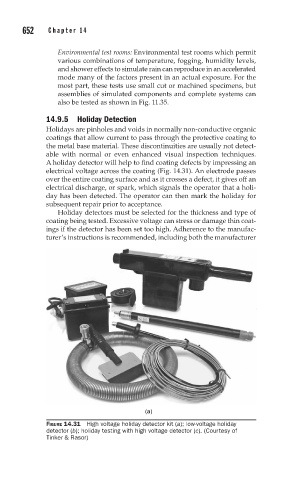

14.9.5 Holiday Detection

Holidays are pinholes and voids in normally non-conductive organic

coatings that allow current to pass through the protective coating to

the metal base material. These discontinuities are usually not detect-

able with normal or even enhanced visual inspection techniques.

A holiday detector will help to find coating defects by impressing an

electrical voltage across the coating (Fig. 14.31). An electrode passes

over the entire coating surface and as it crosses a defect, it gives off an

electrical discharge, or spark, which signals the operator that a holi-

day has been detected. The operator can then mark the holiday for

subsequent repair prior to acceptance.

Holiday detectors must be selected for the thickness and type of

coating being tested. Excessive voltage can stress or damage thin coat-

ings if the detector has been set too high. Adherence to the manufac-

turer’s instructions is recommended, including both the manufacturer

(a)

FIGURE 14.31 High voltage holiday detector kit (a); low-voltage holiday

detector (b); holiday testing with high voltage detector (c). (Courtesy of

Tinker & Rasor)