Page 35 - Defrosting for Air Source Heat Pump

P. 35

Previous related work: A review 27

pumped into the outdoor coil to melt the frost. When the frost is melted and drained

away from the coil, the ASHP unit returns to heating operation. Apart from requiring a

four-way valve, the RCD does not need anything else. That means the system is simple

and easily installed [77, 78]. The energy used for RCD mainly comes from four

sources: (1) the thermal energy of indoor air, (2) the energy stored in the indoor coil’s

metal, (3) the electricity input to the indoor air fan, and (4) the electricity input to the

compressor. The defrosting energy is for (1) heating the outdoor coil’s metal, (2) melt-

ing the frost, (3) heating the melted frost, (4) vaporizing the retained water, and (5)

heating the ambient air. With sufficient energy supply, the duration of an RCD oper-

ation can be much shorter than that of hot gas bypass defrosting. In fact, RCD has been

the most widely used standard defrosting method for ASHP units for many years.

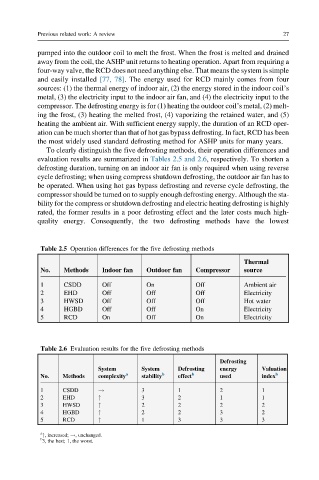

To clearly distinguish the five defrosting methods, their operation differences and

evaluation results are summarized in Tables 2.5 and 2.6, respectively. To shorten a

defrosting duration, turning on an indoor air fan is only required when using reverse

cycle defrosting; when using compress shutdown defrosting, the outdoor air fan has to

be operated. When using hot gas bypass defrosting and reverse cycle defrosting, the

compressor should be turned on to supply enough defrosting energy. Although the sta-

bility for the compress or shutdown defrosting and electric heating defrosting is highly

rated, the former results in a poor defrosting effect and the later costs much high-

quality energy. Consequently, the two defrosting methods have the lowest

Table 2.5 Operation differences for the five defrosting methods

Thermal

No. Methods Indoor fan Outdoor fan Compressor source

1 CSDD Off On Off Ambient air

2 EHD Off Off Off Electricity

3 HWSD Off Off Off Hot water

4 HGBD Off Off On Electricity

5 RCD On Off On Electricity

Table 2.6 Evaluation results for the five defrosting methods

Defrosting

System System Defrosting energy Valuation

No. Methods complexity a stability b effect b used index b

1 CSDD ! 3 1 2 1

2 EHD " 3 2 1 1

3 HWSD " 2 2 2 2

4 HGBD " 2 2 3 2

5 RCD " 1 3 3 3

a

", increased; !, unchanged.

b

3, the best; 1, the worst.