Page 277 - Design and Operation of Heat Exchangers and their Networks

P. 277

Optimal design of heat exchanger networks 263

180

160

Q HU,min

140

120

t (°C)

100

Dt m

80 Q CU,min

60

Dt m

40

0 10,000 20,000 30,000 40,000

H (kW)

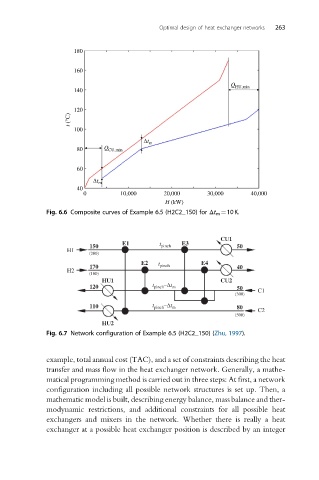

Fig. 6.6 Composite curves of Example 6.5 (H2C2_150) for Δt m ¼10K.

CU1

E1 t E3

150 pinch 50

H1

(200)

E2 t E4

170 pinch 40

H2

(100)

HU1 CU2

120 t pinch –Dt m 50 C1

(300)

110 t pinch –Dt m 80

C2

(500)

HU2

Fig. 6.7 Network configuration of Example 6.5 (H2C2_150) (Zhu, 1997).

example, total annual cost (TAC), and a set of constraints describing the heat

transfer and mass flow in the heat exchanger network. Generally, a mathe-

matical programming method is carried out in three steps: At first, a network

configuration including all possible network structures is set up. Then, a

mathematic model is built, describing energy balance, mass balance and ther-

modynamic restrictions, and additional constraints for all possible heat

exchangers and mixers in the network. Whether there is really a heat

exchanger at a possible heat exchanger position is described by an integer