Page 415 - Design and Operation of Heat Exchangers and their Networks

P. 415

398 Design and operation of heat exchangers and their networks

the measurement is acceptable. The local heat transfer coefficient can then

be determined as

q

α z j ¼ (8.24)

t w,i z j tz j

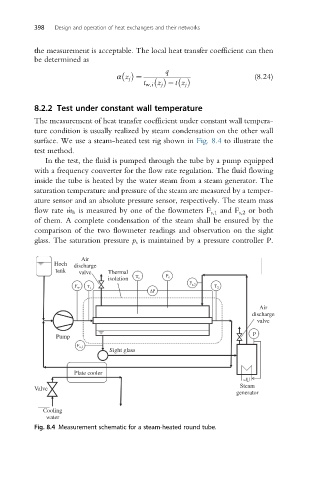

8.2.2 Test under constant wall temperature

The measurement of heat transfer coefficient under constant wall tempera-

ture condition is usually realized by steam condensation on the other wall

surface. We use a steam-heated test rig shown in Fig. 8.4 to illustrate the

test method.

In the test, the fluid is pumped through the tube by a pump equipped

with a frequency converter for the flow rate regulation. The fluid flowing

inside the tube is heated by the water steam from a steam generator. The

saturation temperature and pressure of the steam are measured by a temper-

ature sensor and an absolute pressure sensor, respectively. The steam mass

flow rate _m h is measured by one of the flowmeters F s,1 and F s,2 or both

of them. A complete condensation of the steam shall be ensured by the

comparison of the two flowmeter readings and observation on the sight

glass. The saturation pressure p s is maintained by a pressure controller P.

Air

Hoch discharge

tank valve Thermal

isolation T s P s

F s,2

F w T 1 T 2

ΔP

Air

discharge

valve

Pump P

F s,1

Sight glass

Plate cooler

~U

Steam

Valve

generator

Cooling

water

Fig. 8.4 Measurement schematic for a steam-heated round tube.