Page 104 - Design for Six Sigma a Roadmap for Product Development

P. 104

Product Development Process and Design for Six Sigma 79

Overall, this principle stresses the importance of even job flow and

avoidance of batch queues and overloading of the capacity of the queu-

ing system. This principle makes perfect sense in queuing theory.

Improved stage gate process. As we discussed in the last section, the

stage gate process is an effective way to control the risks involved in the

product development process. However, from a queuing theory perspec-

tive, stage gate is a typical batch queue, as illustrated in Fig. 3.11.

In Fig. 3.11, the projects are like customers in the queue; the strict

stage gate practice means that nobody can cross the phase gate unless

all the customers are served by the server in phase 1. The finished cus-

tomers have to stay in phase 1 until the last customer is served, then

all the people flood into the next phase.

Obviously, this is a slow and ineffective approach. Clark and

Fujimori (1991) discussed the stage overlapping approach to over-

come this deficiency. The idea of stage overlapping is illustrated in

Fig. 3.12.

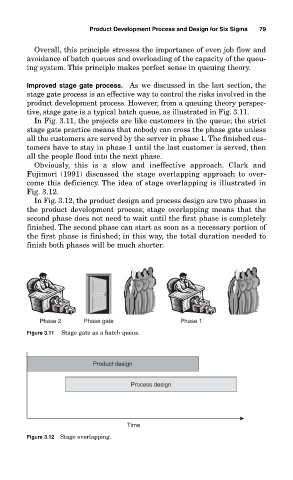

In Fig. 3.12, the product design and process design are two phases in

the product development process; stage overlapping means that the

second phase does not need to wait until the first phase is completely

finished. The second phase can start as soon as a necessary portion of

the first phase is finished; in this way, the total duration needed to

finish both phases will be much shorter.

Phase 2 Phase gate Phase 1

Figure 3.11 Stage gate as a batch queue.

Product design

Process design

Time

Figure 3.12 Stage overlapping.