Page 45 - Design for Six Sigma a Roadmap for Product Development

P. 45

Six Sigma and Lean Fundamentals 23

Materials

Procedures

Methods

Products

Information

(including

specifications)

People Services

Process

Skills

Information

Knowledge

Training

Paperwork

Plant/

equipment

Inputs Outputs

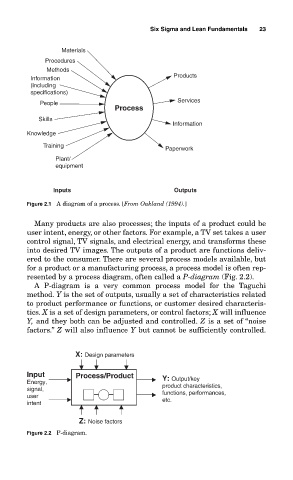

Figure 2.1 A diagram of a process. [From Oakland (1994).]

Many products are also processes; the inputs of a product could be

user intent, energy, or other factors. For example, a TV set takes a user

control signal, TV signals, and electrical energy, and transforms these

into desired TV images. The outputs of a product are functions deliv-

ered to the consumer. There are several process models available, but

for a product or a manufacturing process, a process model is often rep-

resented by a process diagram, often called a P-diagram (Fig. 2.2).

A P-diagram is a very common process model for the Taguchi

method. Y is the set of outputs, usually a set of characteristics related

to product performance or functions, or customer desired characteris-

tics. X is a set of design parameters, or control factors; X will influence

Y, and they both can be adjusted and controlled. Z is a set of “noise

factors.” Z will also influence Y but cannot be sufficiently controlled.

X: Design parameters

Input Process/Product

Energy, Y: Output/key

signal, product characteristics,

user functions, performances,

intent etc.

Z: Noise factors

Figure 2.2 P-diagram.