Page 47 - Design for Six Sigma a Roadmap for Product Development

P. 47

Six Sigma and Lean Fundamentals 25

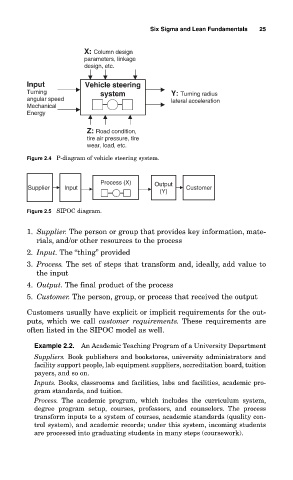

X: Column design

parameters, linkage

design, etc.

Input Vehicle steering

Turning system Y: Turning radius

angular speed lateral acceleration

Mechanical

Energy

Z: Road condition,

tire air pressure, tire

wear, load, etc.

Figure 2.4 P-diagram of vehicle steering system.

Process (X) Output

Supplier Input Customer

(Y)

Figure 2.5 SIPOC diagram.

1. Supplier. The person or group that provides key information, mate-

rials, and/or other resources to the process

2. Input. The “thing” provided

3. Process. The set of steps that transform and, ideally, add value to

the input

4. Output. The final product of the process

5. Customer. The person, group, or process that received the output

Customers usually have explicit or implicit requirements for the out-

puts, which we call customer requirements. These requirements are

often listed in the SIPOC model as well.

Example 2.2. An Academic Teaching Program of a University Department

Suppliers. Book publishers and bookstores, university administrators and

facility support people, lab equipment suppliers, accreditation board, tuition

payers, and so on.

Inputs. Books, classrooms and facilities, labs and facilities, academic pro-

gram standards, and tuition.

Process. The academic program, which includes the curriculum system,

degree program setup, courses, professors, and counselors. The process

transform inputs to a system of courses, academic standards (quality con-

trol system), and academic records; under this system, incoming students

are processed into graduating students in many steps (coursework).