Page 140 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 140

Quality Function Deployment 115

• Study all available information about the service including marketing

plans

• Create innovative ideas, delights, and new wants by investigating

improved functions and cost of ownership and matching service

functions with needs, experience, and customer beliefs

• Innovate to avoid compromising for bottlenecks, conflicts, and constraints

• Benchmark the competition to improve weak areas

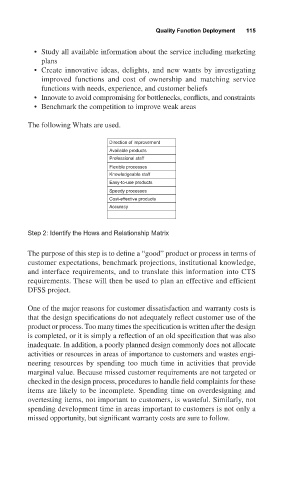

The following Whats are used.

Direction of improvement

Available products

Professional staff

Flexible processes

Knowledgeable staff

Easy-to-use products

Speedy processes

Cost-effective products

Accuracy

Step 2: Identify the Hows and Relationship Matrix

The purpose of this step is to define a “good” product or process in terms of

customer expectations, benchmark projections, institutional knowledge,

and interface requirements, and to translate this information into CTS

requirements. These will then be used to plan an effective and efficient

DFSS project.

One of the major reasons for customer dissatisfaction and warranty costs is

that the design specifications do not adequately reflect customer use of the

product or process. Too many times the specification is written after the design

is completed, or it is simply a reflection of an old specification that was also

inadequate. In addition, a poorly planned design commonly does not allocate

activities or resources in areas of importance to customers and wastes engi-

neering resources by spending too much time in activities that provide

marginal value. Because missed customer requirements are not targeted or

checked in the design process, procedures to handle field complaints for these

items are likely to be incomplete. Spending time on overdesigning and

overtesting items, not important to customers, is wasteful. Similarly, not

spending development time in areas important to customers is not only a

missed opportunity, but significant warranty costs are sure to follow.