Page 210 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 210

Value Engineering 181

How Select Review

vendor bids

Scope Assure

competence

Lease Construct Award Secure Prepare Develop

dealership facility purchase order approvals proposal layout

Establish

budget

Resolve

restriction

When Purchase

property

Why Scope

Analyze Secure Obtain Assign Issue Obtain

conditions option data responsibility authorization approval

Estimate

cost

Identify

requirements

Negotiate

contract

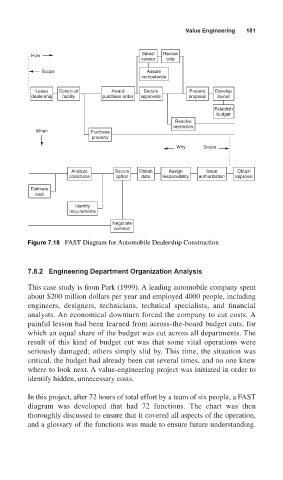

Figure 7.18 FAST Diagram for Automobile Dealership Construction

7.8.2 Engineering Department Organization Analysis

This case study is from Park (1999). A leading automobile company spent

about $200 million dollars per year and employed 4000 people, including

engineers, designers, technicians, technical specialists, and financial

analysts. An economical downturn forced the company to cut costs. A

painful lesson had been learned from across-the-board budget cuts, for

which an equal share of the budget was cut across all departments. The

result of this kind of budget cut was that some vital operations were

seriously damaged; others simply slid by. This time, the situation was

critical, the budget had already been cut several times, and no one knew

where to look next. A value-engineering project was initiated in order to

identify hidden, unnecessary costs.

In this project, after 72 hours of total effort by a team of six people, a FAST

diagram was developed that had 72 functions. The chart was then

thoroughly discussed to ensure that it covered all aspects of the operation,

and a glossary of the functions was made to ensure future understanding.