Page 40 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 40

22 Chapter One

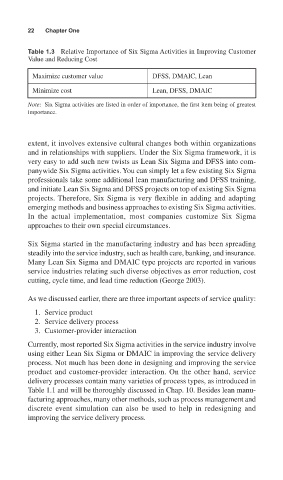

Table 1.3 Relative Importance of Six Sigma Activities in Improving Customer

Value and Reducing Cost

Maximize customer value DFSS, DMAIC, Lean

Minimize cost Lean, DFSS, DMAIC

Note: Six Sigma activities are listed in order of importance, the first item being of greatest

importance.

extent, it involves extensive cultural changes both within organizations

and in relationships with suppliers. Under the Six Sigma framework, it is

very easy to add such new twists as Lean Six Sigma and DFSS into com-

panywide Six Sigma activities. You can simply let a few existing Six Sigma

professionals take some additional lean manufacturing and DFSS training,

and initiate Lean Six Sigma and DFSS projects on top of existing Six Sigma

projects. Therefore, Six Sigma is very flexible in adding and adapting

emerging methods and business approaches to existing Six Sigma activities.

In the actual implementation, most companies customize Six Sigma

approaches to their own special circumstances.

Six Sigma started in the manufacturing industry and has been spreading

steadily into the service industry, such as health care, banking, and insurance.

Many Lean Six Sigma and DMAIC type projects are reported in various

service industries relating such diverse objectives as error reduction, cost

cutting, cycle time, and lead time reduction (George 2003).

As we discussed earlier, there are three important aspects of service quality:

1. Service product

2. Service delivery process

3. Customer-provider interaction

Currently, most reported Six Sigma activities in the service industry involve

using either Lean Six Sigma or DMAIC in improving the service delivery

process. Not much has been done in designing and improving the service

product and customer-provider interaction. On the other hand, service

delivery processes contain many varieties of process types, as introduced in

Table 1.1 and will be thoroughly discussed in Chap. 10. Besides lean manu-

facturing approaches, many other methods, such as process management and

discrete event simulation can also be used to help in redesigning and

improving the service delivery process.