Page 452 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 452

410 Chapter Eleven

the total spread of the specification is six times the standard deviation on

each side of the mean. For a Six Sigma quality level,

C = USL − LSL = 12s = 2

p 6s 6s

By using the normal probability distribution, it can be computed that

P(y will be in specification) = P(LSL ≤ y ≤ USL) = P(−6 ≤ z ≤ 6)

= 0.999999998 = 99.9999998%

Clearly, P(y will be out of specification) =1 – 0.9999999998 = 0.000000002,

or 0.002 defective parts per million. Similarly, if the spread of specification

is 5 times s on each side of the mean, it is called 5 sigma quality.

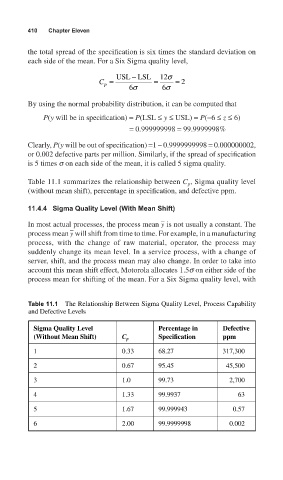

Table 11.1 summarizes the relationship between C , Sigma quality level

p

(without mean shift), percentage in specification, and defective ppm.

11.4.4 Sigma Quality Level (With Mean Shift)

_

In most actual processes, the process mean y is not usually a constant. The

_

process mean y will shift from time to time. For example, in a manufacturing

process, with the change of raw material, operator, the process may

suddenly change its mean level. In a service process, with a change of

server, shift, and the process mean may also change. In order to take into

account this mean shift effect, Motorola allocates 1.5s on either side of the

process mean for shifting of the mean. For a Six Sigma quality level, with

Table 11.1 The Relationship Between Sigma Quality Level, Process Capability

and Defective Levels

Sigma Quality Level Percentage in Defective

(Without Mean Shift) C p Specification ppm

1 0.33 68.27 317,300

2 0.67 95.45 45,500

3 1.0 99.73 2,700

4 1.33 99.9937 63

5 1.67 99.999943 0.57

6 2.00 99.9999998 0.002