Page 451 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 451

Statistical Basics and Six Sigma Metrics 409

Process capability of film thickness

LSL USL

Process data Within

LSL 460.00000 Overall

Target *

Potential (within) capability

USL 660.00000

Sample mean 572.02128 Cp 1.35

Sample?N 47 CPL 1.51

StDev (within) 24.66804 CPU 1.19

StDev (overall) 24.66804 Cpk 1.19

CCpk 1.35

Overall capability

Pp 1.35

PPL 1.51

PPU 1.19

Ppk 1.19

Cpm *

480 510 540 570 600 630 660

Observed performance Exp. within performance Exp. overall performance

PPM?<?LSL 0.00 PPM?<?LSL 2.80 PPM?<?LSL 2.80

PPM?>?USL 0.00 PPM?>?USL 180.89 PPM?>?USL 180.89

PPM?Total 0.00 PPM?Total 183.68 PPM?Total 183.68

11.4.3 Sigma Quality Level (Without Mean Shift)

In 1988, the Motorola Corporation was the winner of the Malcolm Baldrige

National Quality Award. Motorola bases much of its quality effort on its Six

Sigma program. The goal of this program was to reduce the variation in

every process to such an extent that a spread of 12s (6s on each side of the

mean) fits within the process specification limits.

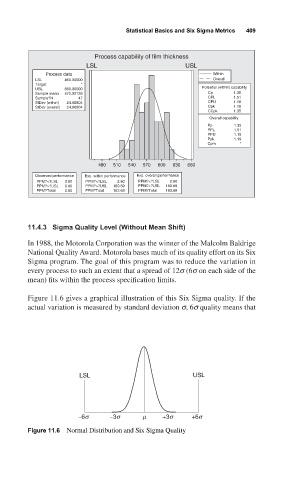

Figure 11.6 gives a graphical illustration of this Six Sigma quality. If the

actual variation is measured by standard deviation s,6s quality means that

LSL USL

−6s −3s m +3s +6s

Figure 11.6 Normal Distribution and Six Sigma Quality