Page 111 - Design of Simple and Robust Process Plants

P. 111

96 Chapter 4 Process Synthesis and Design Optimization

Larger-scale reactor systems Simplification can also be considered from a size per-

spective. Many processes are considered to be restricted by size, and therefore many

reactor systems are doubled, tripled, or even quadrupled. A closer inspection of

these systems shows that different types of constraint are in existence:

. mechanical design;

. mechanical fabrication;

. flow distribution; and

. process-wise, or a combination of these.

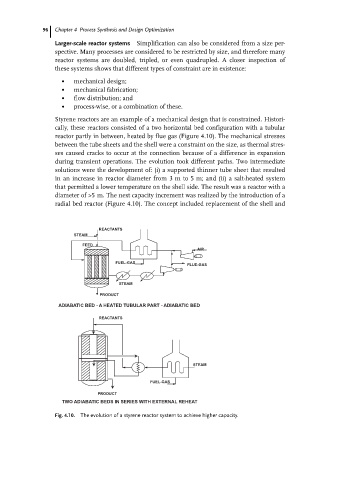

Styrene reactors are an example of a mechanical design that is constrained. Histori-

cally, these reactors consisted of a two horizontal bed configuration with a tubular

reactor partly in between, heated by flue gas (Figure 4.10). The mechanical stresses

between the tube sheets and the shell were a constraint on the size, as thermal stres-

ses caused cracks to occur at the connection because of a difference in expansion

during transient operations. The evolution took different paths. Two intermediate

solutions were the development of: (i) a supported thinner tube sheet that resulted

in an increase in reactor diameter from 3 m to 5 m; and (ii) a salt-heated system

that permitted a lower temperature on the shell side. The result was a reactor with a

diameter of >5 m. The next capacity increment was realized by the introduction of a

radial bed reactor (Figure 4.10). The concept included replacement of the shell and

REACTANTS

STEAM

FEED

AIR

FUEL-GAS

FLUE-GAS

STEAM

PRODUCT

ADIABATIC BED - A HEATED TUBULAR PART - ADIABATIC BED

REACTANTS

STEAM

FUEL-GAS

PRODUCT

TWO ADIABATIC BEDS IN SERIES WITH EXTERNAL REHEAT

Fig. 4.10. The evolution of a styrene reactor system to achieve higher capacity.