Page 167 - Design of Simple and Robust Process Plants

P. 167

152 Chapter 5 Process Simplification and Intensification Techniques

5.3.2

Distillation

In this Section, the combination of functions within distillation is concentrated on

the separation of three or more product streams. In this respect, refineries have a

long tradition in the removal of more product grades from continuous distillation

units, such as crude stills. In the petroleum industry, these side streams traditionally

had a wide specification range, but today these ranges have been narrowed, this

being achieved by side strippers and improved process control. Batch distillations

are often also utilized for the separation of multiple components in different process

industries. For most applications of continuous distillations in the chemical indus-

try, the objective has been to produce high-purity materials, and therefore more

product streams (more than two) were rarely applied, surprisingly enough even

when pure streams were not a requirement.

The alternatives for a conventional distillation column for over two product

streams are:

. Side streams

. Divided wall column (two columns in one)

. Dephlegmator (rectification and cooling), also known as non-adiabatic rectifi-

cation.

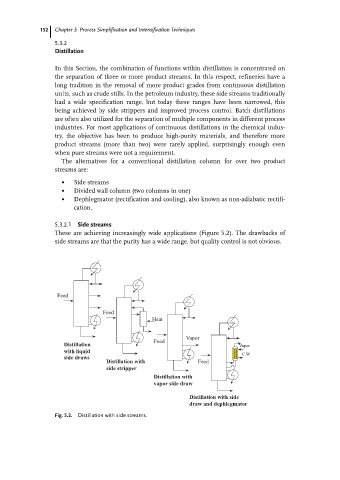

5.3.2.1 Side streams

These are achieving increasingly wide applications (Figure 5.2). The drawbacks of

side streams are that the purity has a wide range, but quality control is not obvious.

Feed

Feed

Heat

Vapor

Feed

Distillation Vapor

with liquid C.W

side draws

Distillation with Feed

side stripper

Distillation with

vapor side draw

Distillation with side

draw and dephlegmator

Fig. 5.2. Distillation with side streams.