Page 171 - Design of Simple and Robust Process Plants

P. 171

156 Chapter 5 Process Simplification and Intensification Techniques

. differences in boiling point between the light and heavy components, to stay

within the normal utility levels for condensing and reboiling; and

. thermal degradation of the products.

Both conditions might force the design towards a two-column set-up operating at

different pressure levels.

5.3.2.3 Dephlegmator

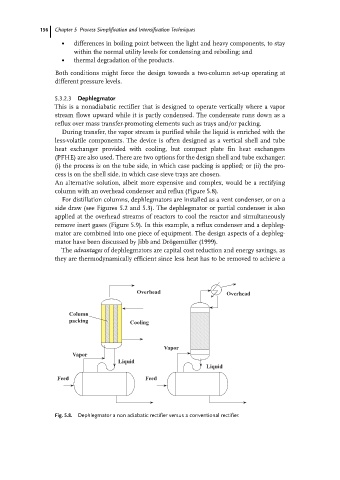

This is a nonadiabatic rectifier that is designed to operate vertically where a vapor

stream flows upward while it is partly condensed. The condensate runs down as a

reflux over mass transfer-promoting elements such as trays and/or packing.

During transfer, the vapor stream is purified while the liquid is enriched with the

less-volatile components. The device is often designed as a vertical shell and tube

heat exchanger provided with cooling, but compact plate fin heat exchangers

(PFHE) are also used. There are two options for the design shell and tube exchanger:

(i) the process is on the tube side, in which case packing is applied; or (ii) the pro-

cess is on the shell side, in which case sieve trays are chosen.

An alternative solution, albeit more expensive and complex, would be a rectifying

column with an overhead condenser and reflux (Figure 5.8).

For distillation columns, dephlegmators are installed as a vent condenser, or on a

side draw (see Figures 5.2 and 5.3). The dephlegmator or partial condenser is also

applied at the overhead streams of reactors to cool the reactor and simultaneously

remove inert gases (Figure 5.9). In this example, a reflux condenser and a dephleg-

mator are combined into one piece of equipment. The design aspects of a dephleg-

mator have been discussed by Jibb and Drögemüller (1999).

The advantages of dephlegmators are capital cost reduction and energy savings, as

they are thermodynamically efficient since less heat has to be removed to achieve a

Overhead Overhead

Column

packing Cooling

Vapor

Vapor

Liquid

Liquid

Feed Feed

Fig. 5.8. Dephlegmator a non adiabatic rectifier versus a conventional rectifier.