Page 174 - Design of Simple and Robust Process Plants

P. 174

5.3 Combination of Process Functions 159

lights

lights feed

unconverted

Reactor

feed reactant reactor

crude

crude reactor feed

product

Reactor

Products

Products

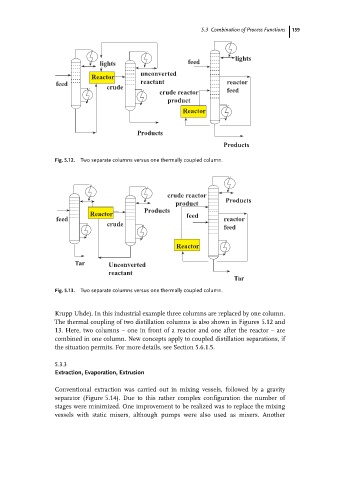

Fig. 5.12. Two separate columns versus one thermally coupled column.

crude reactor

Products

product

Products

Reactor feed

feed reactor

crude

feed

Reactor

Tar Unconverted

reactant

Tar

Fig. 5.13. Two separate columns versus one thermally coupled column.

Krupp Uhde). In this industrial example three columns are replaced by one column.

The thermal coupling of two distillation columns is also shown in Figures 5.12 and

13. Here, two columns ± one in front of a reactor and one after the reactor ± are

combined in one column. New concepts apply to coupled distillation separations, if

the situation permits. For more details, see Section 5.6.1.5.

5.3.3

Extraction, Evaporation, Extrusion

Conventional extraction was carried out in mixing vessels, followed by a gravity

separator (Figure 5.14). Due to this rather complex configuration the number of

stages were minimized. One improvement to be realized was to replace the mixing

vessels with static mixers, although pumps were also used as mixers. Another