Page 178 - Design of Simple and Robust Process Plants

P. 178

5.3 Combination of Process Functions 163

In case a gas turbine is not foreseen, the cascade cooling follows the following steps:

(i) high-temperature process heating; (ii) medium-temperature process heating; and

(iii) air and fuel preheating.

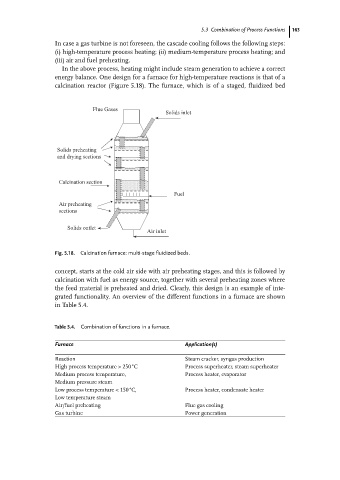

In the above process, heating might include steam generation to achieve a correct

energy balance. One design for a furnace for high-temperature reactions is that of a

calcination reactor (Figure 5.18). The furnace, which is of a staged, fluidized bed

Flue Gases

Solids inlet

Solids preheating

and drying sections

Calcination section

Fuel

Air preheating

sections

Solids outlet

Air inlet

Fig. 5.18. Calcination furnace: multi-stage fluidized beds.

concept, starts at the cold air side with air preheating stages, and this is followed by

calcination with fuel as energy source, together with several preheating zones where

the feed material is preheated and dried. Clearly, this design is an example of inte-

grated functionality. An overview of the different functions in a furnace are shown

in Table 5.4.

Table 5.4. Combination of functions in a furnace.

Furnace Application(s)

Reaction Steam cracker, syngas production

High process temperature > 250 C Process superheater, steam superheater

Medium process temperature, Process heater, evaporator

Medium pressure steam

Low process temperature < 150 C, Process heater, condensate heater

Low temperature steam

Air/fuel preheating Flue gas cooling

Gas turbine Power generation