Page 180 - Design of Simple and Robust Process Plants

P. 180

5.4 Integration of Process Equipment 165

REACTANTS

STEAM

FEED

AIR

FUEL-GAS FLUE-GAS

STEAM

CRUDE PRODUCT

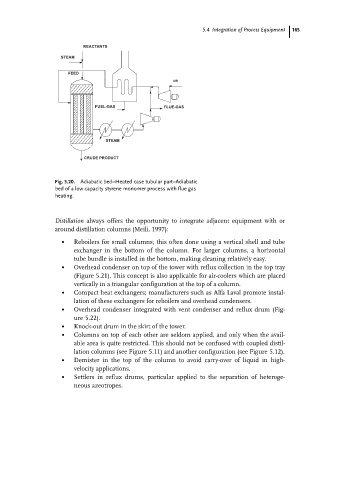

Fig. 5.20. Adiabatic bed±Heated case tubular part±Adiabatic

bed of a low capacity styrene monomer process with flue gas

heating.

Distillation always offers the opportunity to integrate adjacent equipment with or

around distillation columns (Meili, 1997):

. Reboilers for small columns; this often done using a vertical shell and tube

exchanger in the bottom of the column. For larger columns, a horizontal

tube bundle is installed in the bottom, making cleaning relatively easy.

. Overhead condenser on top of the tower with reflux collection in the top tray

(Figure 5.21). This concept is also applicable for air-coolers which are placed

vertically in a triangular configuration at the top of a column.

. Compact heat exchangers; manufacturers such as Alfa Laval promote instal-

lation of these exchangers for reboilers and overhead condensers.

. Overhead condenser integrated with vent condenser and reflux drum (Fig-

ure 5.22).

. Knock-out drum in the skirt of the tower.

. Columns on top of each other are seldom applied, and only when the avail-

able area is quite restricted. This should not be confused with coupled distil-

lation columns (see Figure 5.11) and another configuration (see Figure 5.12).

. Demister in the top of the column to avoid carry-over of liquid in high-

velocity applications.

. Settlers in reflux drums, particular applied to the separation of heteroge-

neous azeotropes.