Page 169 - Design of Simple and Robust Process Plants

P. 169

154 Chapter 5 Process Simplification and Intensification Techniques

PRODUCT A PRODUCT A

FEED FEED

STEAM

STEAM

STEAM STEAM

PRODUCT B

PRODUCT B

PRODUCT C PRODUCT C

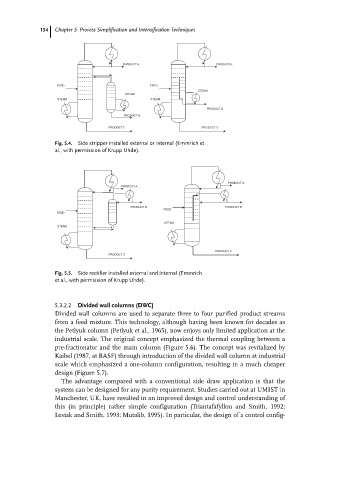

Fig. 5.4. Side stripper installed external or internal (Emmrich et

al., with permission of Krupp Uhde).

PRODUCT A

PRODUCT A

PRODUCT B PRODUCT B

FEED

FEED

STEAM

STEAM

PRODUCT C

PRODUCT C

Fig. 5.5. Side rectifier installed external and internal (Emmrich

et al., with permission of Krupp Uhde).

5.3.2.2 Divided wall columns (DWC)

Divided wall columns are used to separate three to four purified product streams

from a feed mixture. This technology, although having been known for decades as

the Petlyuk column (Petlyuk et al., 1965), now enjoys only limited application at the

industrial scale. The original concept emphasized the thermal coupling between a

pre-fractionator and the main column (Figure 5.6). The concept was revitalized by

Kaibel (1987, at BASF) through introduction of the divided wall column at industrial

scale which emphasized a one-column configuration, resulting in a much cheaper

design (Figure 5.7).

The advantage compared with a conventional side draw application is that the

system can be designed for any purity requirement. Studies carried out at UMIST in

Manchester, UK, have resulted in an improved design and control understanding of

this (in principle) rather simple configuration (Triantafafyllou and Smith, 1992;

Lestak and Smith, 1993; Mutalib, 1995). In particular, the design of a control config-