Page 318 - Design of Simple and Robust Process Plants

P. 318

304 Chapter 8 Instrumentation, Automation of Operation and Control

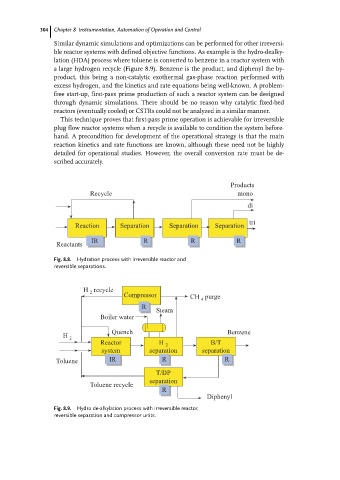

Similar dynamic simulations and optimizations can be performed for other irreversi-

ble reactor systems with defined objective functions. As example is the hydro-dealky-

lation (HDA) process where toluene is converted to benzene in a reactor system with

a large hydrogen recycle (Figure 8.9). Benzene is the product, and diphenyl the by-

product, this being a non-catalytic exothermal gas-phase reaction performed with

excess hydrogen, and the kinetics and rate equations being well-known. A problem-

free start-up, first-pass prime production of such a reactor system can be designed

through dynamic simulations. There should be no reason why catalytic fixed-bed

reactors (eventually cooled) or CSTRs could not be analyzed in a similar manner.

This technique proves that first-pass prime operation is achievable for irreversible

plug flow reactor systems when a recycle is available to condition the system before-

hand. A precondition for development of the operational strategy is that the main

reaction kinetics and rate functions are known, although these need not be highly

detailed for operational studies. However, the overall conversion rate must be de-

scribed accurately.

Products

Recycle mono

di

tri

Reaction Separation Separation Separation

IR R R R R R R

IR

Reactants

Fig. 8.8. Hydration process with irreversible reactor and

reversible separations.

H recycle

2

Compressor CH purge

4

R R Steam

Boiler water

Quench Benzene

H

2

Reactor H 2 B/T

system separation separation

IR

Toluene IR R R R R

T/DP

separation

Toluene recycle

R R

Diphenyl

Fig. 8.9. Hydro de-alkylation process with irreversible reactor,

reversible separation and compressor units.