Page 316 - Design of Simple and Robust Process Plants

P. 316

302 Chapter 8 Instrumentation, Automation of Operation and Control

± z is axial reactor position

± a 1 decrease rate parameter for reactor inlet temperature

± a 2 increase parameter for flow rate

± u i is total reactor flow rate

± C B is concentration of reactant B

± w B is concentration of reactant B at the reactor inlet

± m h is the trajectory of the inlet temperature over time

± r is time

± h is temperature

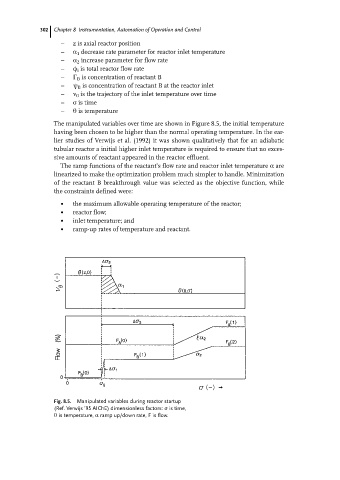

The manipulated variables over time are shown in Figure 8.5, the initial temperature

having been chosen to be higher than the normal operating temperature. In the ear-

lier studies of Verwijs et al. (1992) it was shown qualitatively that for an adiabatic

tubular reactor a initial higher inlet temperature is required to ensure that no exces-

sive amounts of reactant appeared in the reactor effluent.

The ramp functions of the reactant's flow rate and reactor inlet temperature a are

linearized to make the optimization problem much simpler to handle. Minimization

of the reactant B breakthrough value was selected as the objective function, while

the constraints defined were:

. the maximum allowable operating temperature of the reactor;

. reactor flow;

. inlet temperature; and

. ramp-up rates of temperature and reactant.

Fig. 8.5. Manipulated variables during reactor startup

(Ref. Verwijs '95 AIChE) dimensionless factors: r is time,

h is temperature, a ramp up/down rate, F is flow.